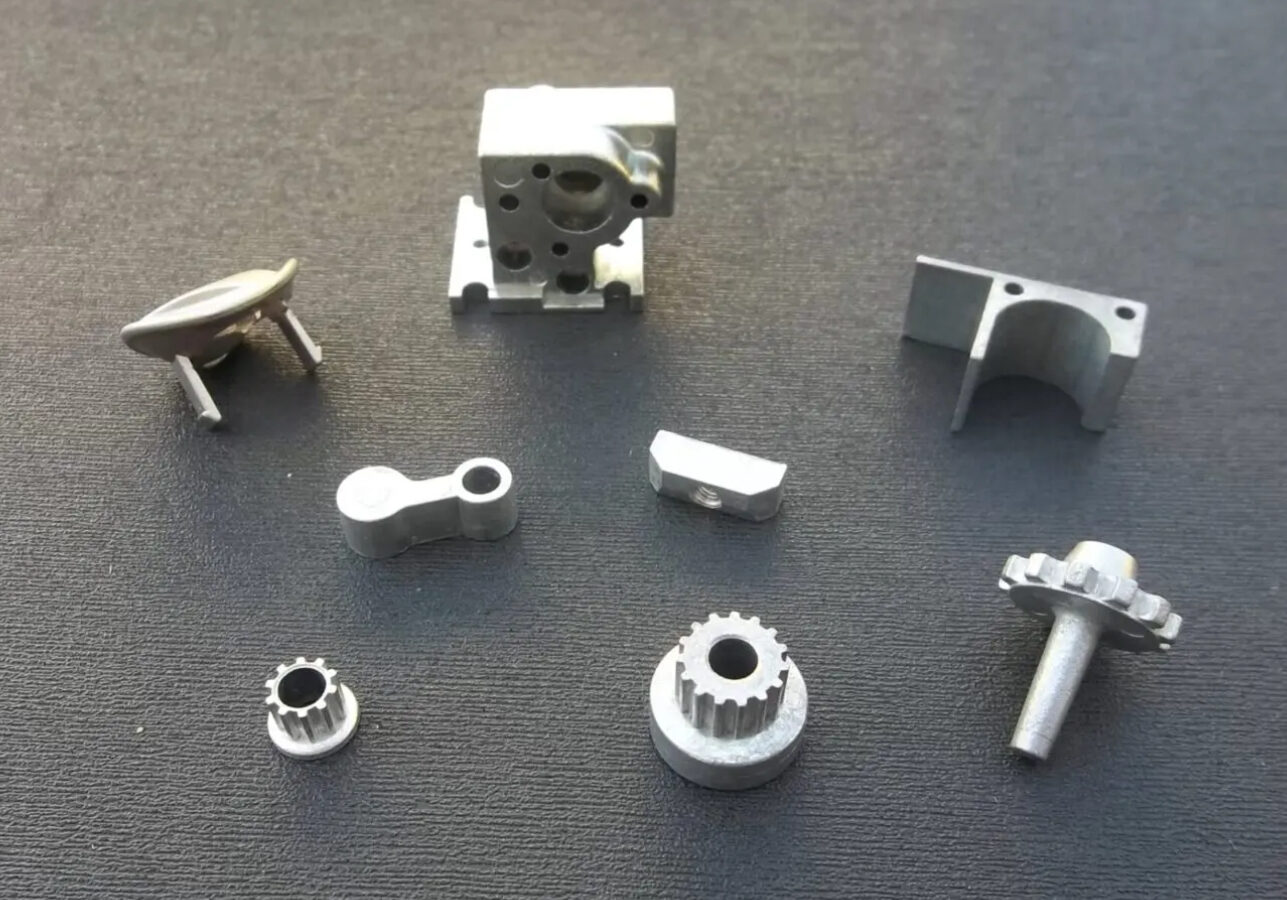

Our Capabilities

Quality Die-Castings at a Competitive Price!

At Connecticut Precision Castings in Claremont, New Hampshire, our casting machines are hot chamber machines with a locking pressure of 30 tons, and each machine can produce up to 4,500 parts per day in an 8-hour day with a single cavity mold. We can produce a few hundred parts or up to several hundred thousand parts per year. Our standard orders can range from lots of a few hundred parts up to 50,000 parts or more.

Casting Process

The casting process is fully automated and parts are inspected at regular intervals for key features throughout the entire casting run to ensure a consistent, solid part. Due to the relatively low melting temperature of zinc alloys, the parts cool quickly and can be transported to secondary operations within minutes of casting if necessary.

Tooling for zinc die-casting

The tooling for a zinc's die-cast part is typically much less than tooling for an aluminum cast part and has a significantly longer life, with up to 1 million shots or more being common before any major tool refurbishing is required. Cooling lines and mechanical slides are typically integral to the mold, which makes set-up quick and easy. Often, the tooling can be produced with inserts that would fit into a common mold shoe, which is more cost-effective for the customer.

Secondary Operations

Often, parts require a secondary operation such as reaming, drilling, or removing the gate. Many of these tasks are best done manually as well as light assembly tasks. Most parts are at least tumbled to remove any sharp edges or flash and leave an even surface finish. We have a variety of tumbling media sizes and materials, including plastic, ceramic, and synthetics.

CNC Machining

Our newest addition of equipment has been two CNC Vertical Machining Centers to perform secondary operations such as milling, reaming, drilling, and tapping. By utilizing multiple part fixtures, the operator is allowed more time for other tasks such as loading and unloading the fixtures and part inspections, all while the machines are in operation. This allows the machines to be almost continuously running.

Connect With Our Team

Let us know how we can help! If you have any questions about us and our zinc die-casting, send us a message anytime.